End-to-end solutions for discrete manufacturing

Whether you’re in the business of manufacturing automotive spare parts, plastic packaging, machinery and components, or toys and furniture, the pressure is mounting for more innovative and better-quality products, shorter product lifecycles and stricter compliance to safety and environmental regulations. An ERP solution built by Microsoft and delivered with customizations to your business by Rand Group can transform your day-to-day operations, help you overcome challenges discrete manufacturers face, and deliver long-term success.

Achieve manufacturing excellence with a customized ERP solution

Discrete manufacturers that partner with Rand Group for business solutions have increased production throughput, cut production delays, eliminated costly inefficiencies, and boosted the performance of their machinery and industrial assets. Our industry and ERP experts combined with the power of Microsoft technologies deliver connected systems with automated process and data flows throughout your operation and supply chain relationships.

Rand Group is your long-term partner to help you address industry challenges such as improving agility, managing warranties, balancing changing supply and demand, reducing time to market, and more. We have been serving clients in the discrete manufacturing industry – from industrial goods and building materials to steel and oilfield machinery – since 2003, and are a certified Microsoft gold partner.

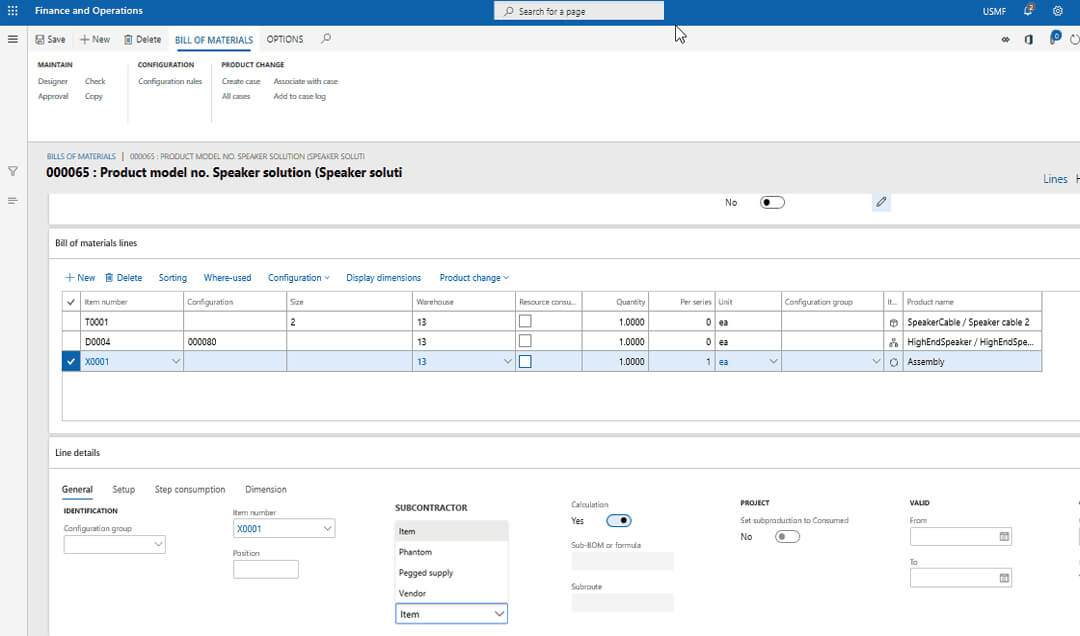

Manage complex bill of materials requirements

With flexibility in how you define and manage your bill of materials, you can provide a complete, up-to-date source of information that eliminates the need for standalone spreadsheets and systems.

Gain control of your product lifecycle

Create a shared and singular version of truth for all item master data. Implement an organized and structured method for handling product changes to reduce delays and go-to-market faster.

Adapt faster to consumer demand

Infuse your planning process with supply chain, sales, and marketing pipeline data to improve demand forecasting so that you can make smarter, better decisions about the future.

White Paper

Four pillars of the digital supply chain

A digital twin strategy can be used to model complex processes that combine physical, digital, and process components—which makes it ideal for modernizing supply chain management and providing a new level of control tower functionality to the business. In this whitepaper, learn more about a digital twin strategy and four pillars to set your supply chain up for long-term success in the digital era.

White Paper

Four pillars of the digital supply chain

A digital twin strategy can be used to model complex processes that combine physical, digital, and process components—which makes it ideal for modernizing supply chain management and providing a new level of control tower functionality to the business. In this whitepaper, learn more about a digital twin strategy and four pillars to set your supply chain up for long-term success in the digital era.

Manage bill of materials with ease

With a discrete manufacturing ERP, your team will have the ability to manage the complexity of various bill of materials (BOMs) in a single platform. Version control allows you to make ongoing changes to an item and set up different configurations based on the circumstance or location. Additionally, you can set expiration dates and phase out old components so that new components can be produced or bought.

Dynamics 365 has the following capabilities to manage your BOMs:

- Create, edit, and copy BOMs, BOM versions, and routes

- Check for errors, including circularity

- View and verify sites the BOM versions are assigned

- Add, edit, and print BOM and BOM lines

- Run a cost or sales price calculation for a product variant

- Approve and activate product changes

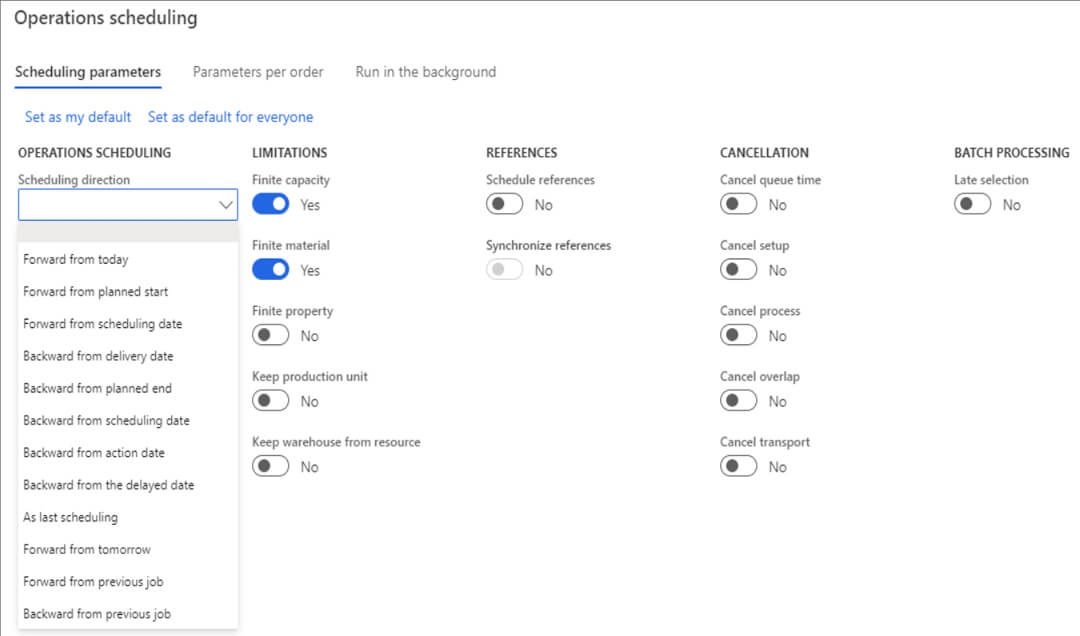

Balance capacity planning and scheduling

Manufacturers understand the importance of planning the production process so that each operation in the production route is assigned a starting and ending date and time, and that the materials needed for production are available when the operation starts.

With Dynamics 365, you can complete the following processes in a single ERP solution:

- Schedule multiple productions in the order of their assigned priority

- Split production orders based on delivery schedule

- Schedule productions based on the capacity of the resources

- Produce an overall schedule for the jobs that are to be performed

- Assign jobs and operations to a resource or resource groups

- Manage and calculate scrap

Build production configuration models

The need to configure a product to meet special requirements is quickly becoming the rule instead of the exception in both B2B and B2C relationships. For a manufacturer, the ability to support configure-to-order scenarios represents an opportunity to carefully respond to the needs of the customer and reduce high costs that are tied to inventory.

Product configuration is an essential tool in your ERP that allows users to quickly satisfy customer requirements by providing access to frequently selected data by using configuration templates. It can save time when you configure items on sales orders, sales quotations, purchase orders, and production orders, and provides a visual overview of the product configuration model structure.

Rand Group’s industry-tailored solutions for discrete manufacturing

Rand Group offers a variety of manufacturing-tailored ERP solutions built by Microsoft to transform the way you run your operations. Our team will help you evaluate and select the best solution for your discrete manufacturing business, then implement and customize it based on your specific processes. Explore solutions below based on your needs.

Dynamics 365 for Manufacturing

Dynamics 365 for Manufacturing is a collection of end-to-end cloud solutions that help securely connect people, assets, workflow, and business processes, empowering manufacturers to be more resilient. It is designed for midsize to large organizations with complex manufacturing operations.

Business Central for Manufacturing

Dynamics 365 Business Central is a comprehensive business management solution on the cloud for small and midsize organizations that helps automate and streamline business processes. It also includes capabilities for managing manufacturing processes.

Dynamics 365 Guides

Dynamics 365 Guides is a mixed-reality application for Microsoft HoloLens that empowers operators to learn during the flow of work using holographic instructions to get jobs done faster, minimize hours, and improve skills.