Simplify operations with Sage Intacct Inventory Management

Inventory control is one of the most critical components of a company’s profitability and customer satisfaction. Knowing what you have, where it is, and what it’s worth directly impacts your financial health. Sage Intacct Inventory Management offers real-time automation and visibility across your supply chain, helping businesses manage stock efficiently from procurement to fulfillment.

For organizations with more complex needs—such as advanced manufacturing, warehouse automation, or multi-site distribution—Sage Distribution and Manufacturing Operations (SDMO) builds on these capabilities, extending Intacct’s financial management foundation into a full operational solution. Together, they enable growing businesses to unify finance, distribution, and production data on one modern cloud platform. In this blog, we’ll explore how Sage Intacct Inventory Management helps businesses gain tighter control over their inventory and improve financial accuracy.

What is inventory management in Sage Intacct?

Sage Intacct Inventory Management is a cloud-based module designed to help organizations maintain optimal stock levels, manage inventory across multiple locations, and gain real-time insight into the value of their goods. It connects seamlessly with purchasing, order entry, and accounting modules to ensure your inventory data flows automatically throughout the system.

Whether you are managing raw materials, finished goods, or non-inventory items, Sage Intacct gives you full control over every stage of the inventory lifecycle—from receipts and transfers to valuation and costing.

At its core, Sage Intacct Inventory Management helps you answer four critical questions:

- What do you have? Track items with detailed records including descriptions, specifications, and custom attributes

- How much do you have? Monitor stock levels in real-time across all locations with automated alerts

- Where is it? Maintain visibility down to the bin level with warehouse, zone, aisle, row, and bin tracking

- What is it worth? Calculate accurate inventory valuations using multiple costing methods aligned with your business requirements

The system supports both inventory and non-inventory items, giving you flexibility in how you manage different product types within your business.

The benefits of inventory management in Sage Intacct

Businesses that implement Sage Intacct Inventory Management gain:

- Improved visibility and accuracy – Access real-time stock levels, location tracking, and transaction histories.

- Better financial control – Automatically calculate true cost of goods sold (COGS) including landed costs such as freight and duties.

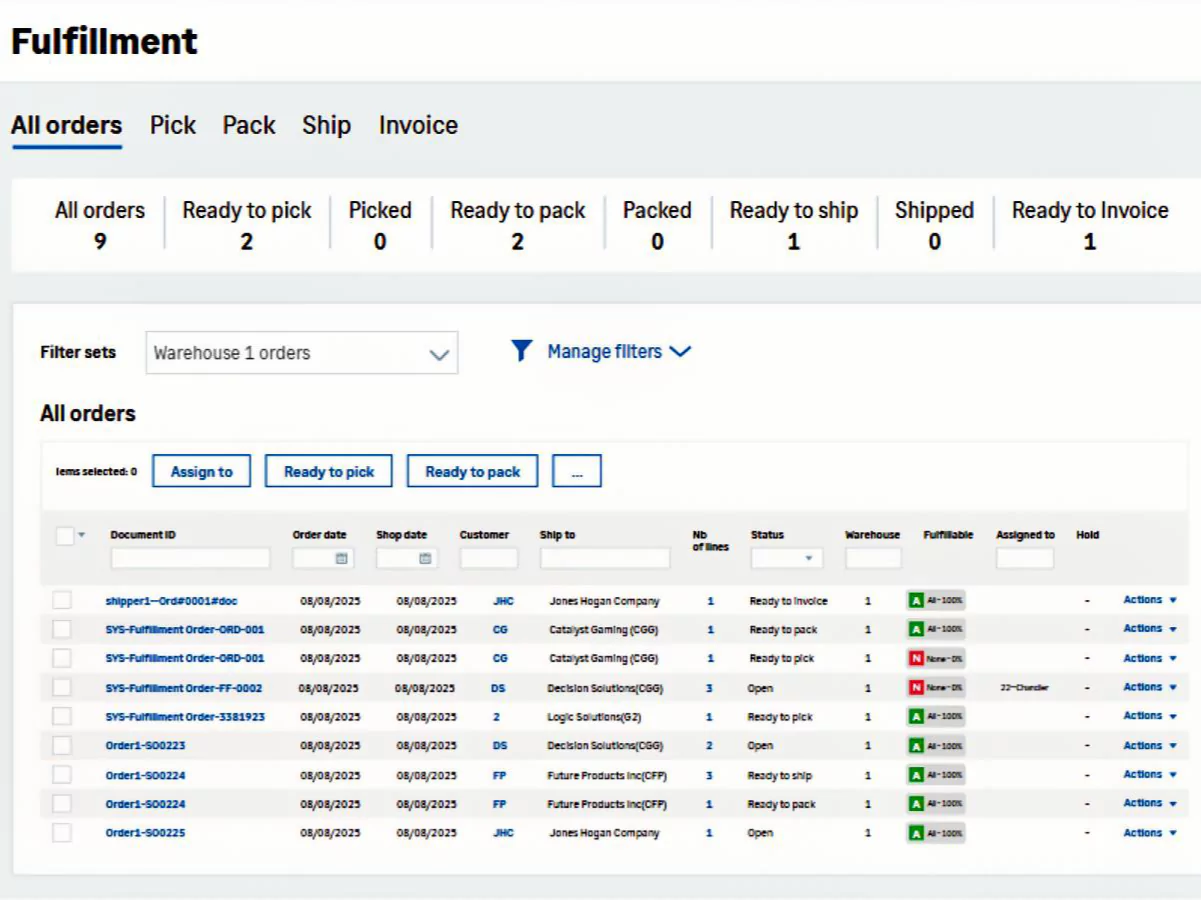

- Faster order fulfillment – Leverage automation for pick, pack, and ship processes while maintaining inventory accuracy.

- Optimized cash flow – Use automated replenishment rules and reorder points to prevent stockouts or overstocking.

- Integrated workflows – Connect inventory with purchasing and order management to streamline operations and reduce manual entry.

- Scalability – Easily expand across new locations, warehouses, or product lines without losing control or visibility.

Optimize inventory performance with Rand Group

Gain a complete view of your stock, reduce costs, and streamline your operations with Sage Intacct Inventory Management.

Key features of inventory management in Sage Intacct

Sage Intacct offers a comprehensive set of tools to manage inventory efficiently and accurately. These features include:

Inventory costing and valuation

Features include:

- Multiple costing methods including FIFO, LIFO, Average, and Standard.

- Automated recalculation to account for prior or later period costs.

- Landed cost allocation to distribute freight, duties, or taxes across items for accurate COGS.

Inventory tracking and visibility

Gain complete visibility into your stock, no matter where it’s located. Sage Intacct provides the tools to track inventory across warehouses and monitor item movements in real time.

Features include:

- Track by warehouse, zone, aisle, row, and bin.

- Manage lot, serial number, and expiration date tracking.

- Real-time stock lookups across multiple locations.

- Define custom units of measure for each item.

Stock level control and replenishment

Ensure optimal stock levels to balance customer satisfaction and cash flow. Sage Intacct automates replenishment and purchasing processes for greater efficiency.

Features include:

- User-defined replenishment processes based on reorder points, forecasts, and seasonal demand.

- Support for economic order quantities and alternate vendors.

Inventory automation (optional add-on)

For businesses looking to modernize warehouse operations, Sage Intacct offers an optional automation module that streamlines data entry and increases accuracy.

Features include:

- Mobile barcode scanning and embedded label printing.

- Real-time data validation and transaction posting at the point of activity.

- Carrier integrations for shipping and customer tracking notifications.

Kitting, assembly, and fulfillment workflows

Simplify light manufacturing and fulfillment processes with kitting and automated stock adjustments.

Features include:

- Create and disassemble kits with automatic stock adjustments.

- Visual pick, pack, and ship dashboards for real-time order management.

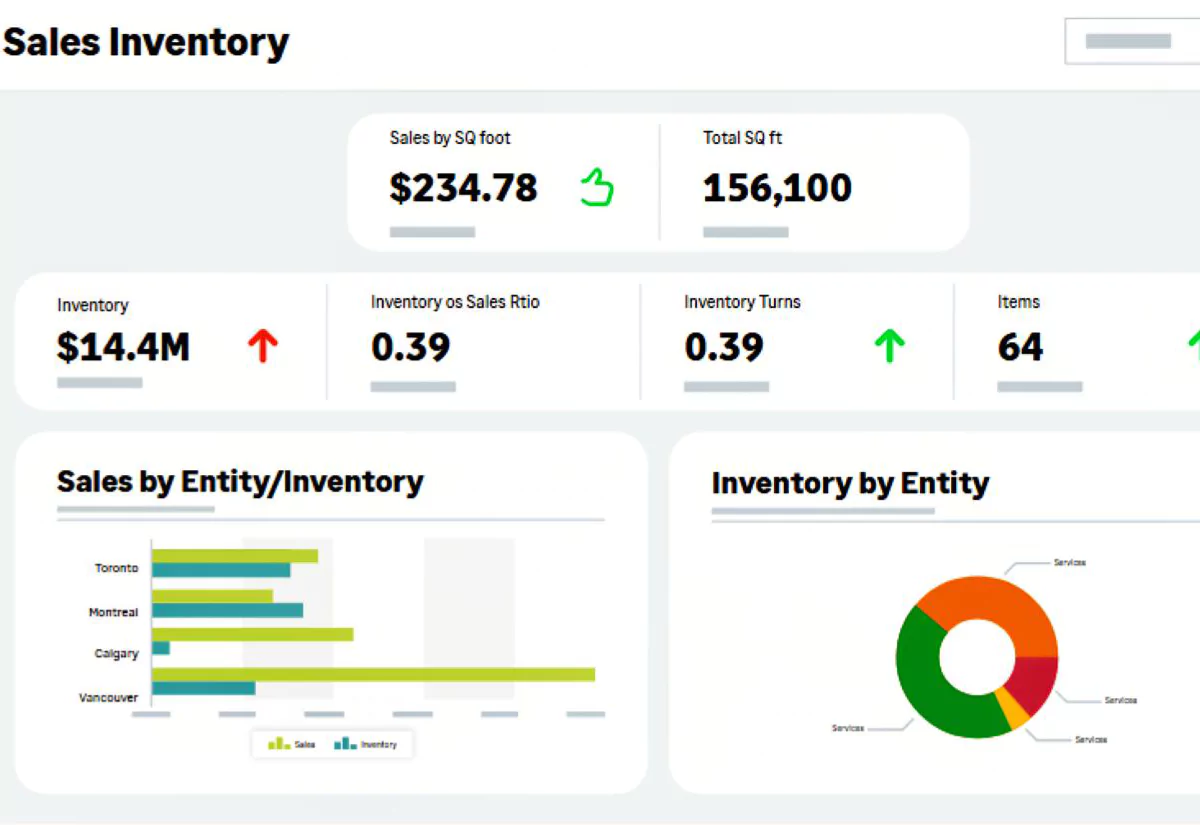

Built-in reporting and analytics

Make informed decisions with accurate, real-time insights into inventory performance and financial impact.

Features include:

- Out-of-the-box inventory reports for status, valuation, cost, activity, and reorders.

- Custom dashboards with item and warehouse dimensions for detailed analysis.

These features are enhanced even further with Sage Distribution and Manufacturing Operations (SDMO), which adds deeper functionality for manufacturing processes, production scheduling, and advanced warehouse operations.

Sage Intacct inventory management vs. SDMO comparison

Sage Intacct inventory management offers essential inventory tracking and valuation for businesses seeking streamlined control across multiple locations, while SDMO enhances these capabilities with advanced manufacturing, warehouse, and distribution workflows for complex operations. Compare both solutions in the chart below to identify which platform best fits your supply chain needs.

Transform your inventory management journey with Rand Group

As a trusted Sage partner, Rand Group provides comprehensive implementation, support, and training services to help your organization unlock the full potential of Sage Intacct inventory management.

Our team ensures that your system is configured to meet your business needs—from setup and customization to user training and reporting design. Whether you’re implementing inventory management for the first time or extending your current Sage Intacct environment, we help you achieve greater visibility, efficiency, and control across your operations.

Frequently asked questions (FAQs)

- Can Sage Intacct track inventory across multiple locations?

Yes. You can track and manage items across multiple warehouses, zones, and bins, with full visibility into quantities and movements in real time. - What costing methods are available?

Sage Intacct supports FIFO, LIFO, Average, and Standard costing methods, allowing you to select the one that best fits your organization. - Can I automate inventory transactions?

Yes, using Sage’s Inventory Automation module, you can scan barcodes, validate data at the point of activity, and automate transactions like receipts, transfers, and counts. - Does Sage Intacct include replenishment or forecasting capabilities?

Yes. You can automate replenishment based on reorder points, demand forecasts, or fluctuating seasonal trends. - What is the difference between Sage Intacct Inventory Management and SDMO?

Inventory Management focuses on tracking, valuation, and replenishment across warehouses. SDMO (Sage Distribution and Manufacturing Operations) expands on these features with advanced manufacturing, warehouse management, and production scheduling tools for more complex operations.

Next steps

Transform your inventory operations with a cloud-based solution that delivers real-time visibility, automation, and scalability.

Contact Rand Group to schedule a consultation and discover how Sage Intacct Inventory Management—or Sage Distribution and Manufacturing Operations—can help you achieve greater control and profitability across your supply chain.