Exploring the latest updates in the NetSuite Manufacturing Mobile app

NetSuite’s latest release, 2024.1, brings significant advancements to its Manufacturing Mobile app, empowering manufacturers with streamlined processes and improved efficiency on the shop floor. These enhancements offer a comprehensive solution to address common challenges faced in manufacturing, ranging from accurate time tracking to seamless inventory management. In this blog, we will review the enhancements to the mobile app as well as the benefits of this release wave.

Benefits of the NetSuite Manufacturing Mobile enhancements

Manufacturers stand to gain several key advantages from the latest enhancements introduced in the NetSuite 2024.1 release:

- Enhanced time and labor management: With the updated Manufacturing Mobile app, manufacturers gain the ability to meticulously track the time and labor invested in each step of the production process.

- Automated inventory management: As factory employees build products, the app automatically deducts the required components from the available inventory, eliminating the need for manual entry.

- Integrated work instructions: Work instructions directly within the application interface can encompass various multimedia elements such as text, images, files, and URLs, providing comprehensive guidance to factory workers during the production process.

- Scan items with UPC code: Users can now conveniently scan items using UPC codes, facilitating swift and accurate identification of components during the production process.

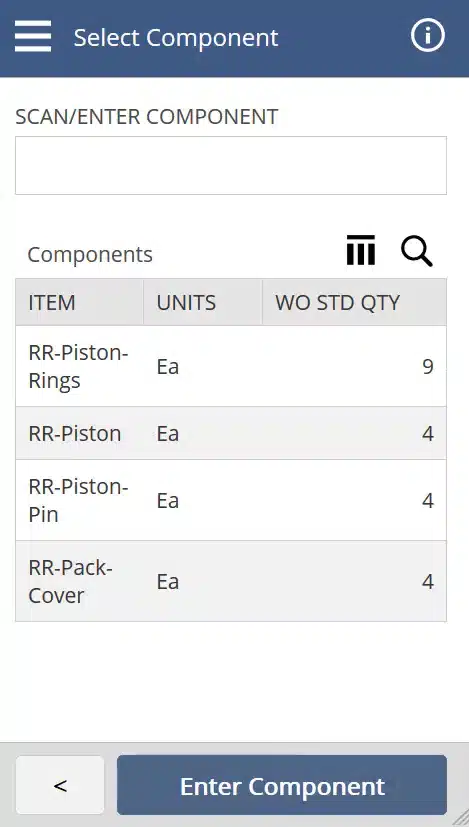

Backflush and issue components when reporting data

In the latest NetSuite Manufacturing Mobile release, users can now seamlessly manage inventory through automated backflushing and component issuing during production reporting. This means that components listed in the Bill of Materials (BOM) are automatically deducted from inventory as products are built, eliminating the need for manual data entry by production workers. This streamlined process enhances efficiency by reducing time spent on inventory management tasks.

Users have the flexibility to designate specific components within the BOM for automatic backflushing when production is reported. This designation can be done at the operation level, ensuring precise control over inventory usage. Additionally, users can manually issue components if necessary, providing further adaptability to production needs.

- Subset designation: Users can select specific BOM components for automatic backflushing, allowing precise inventory management.

- Work order support: Backflushing is compatible with various work order types, including NON-WIP and those with or without routing, ensuring adaptability to diverse manufacturing processes.

- Item compatibility: Backflushing can be applied to non-inventory item types, broadening its utility across different component types.

- “Backflush All Components” option: Users can designate a work order to automatically backflush all components, simplifying inventory handling regardless of individual settings.

- Issue transaction trigger: Before completion, an issue transaction is activated, ensuring accurate tracking of component usage during production.

Overall, this enhancement simplifies inventory management and enhances efficiency in production reporting, offering users greater control and flexibility in managing their manufacturing processes.

Introducing UPC Code Support

In the latest update of the NetSuite Manufacturing Mobile Suite App, users can now easily scan and enter item UPC codes directly into the application. This feature introduces “UPC Code Support” columns for both assembly and component items, allowing users to view and input UPC codes conveniently. Instead of manually entering item names, users can now scan or enter UPC codes, streamlining the data entry process.

It’s important to note that currently, only GS1-128 barcodes are supported for capturing item names. However, a future release is planned to expand this functionality to capture lot and quantity information from barcodes. This enhancement simplifies inventory management by providing a more efficient method for identifying and inputting item information, ultimately improving productivity on the shop floor.

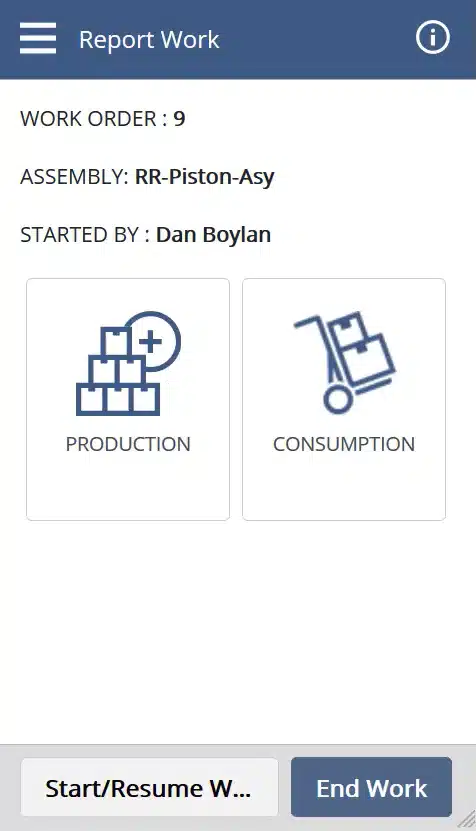

Efficient work order management with time tracking

In the latest update of the NetSuite Manufacturing Mobile Suite App, manufacturers can more accurately calculate the amount of time and labor it takes to complete a work order and identify bottlenecks on the shop floor. This feature allows users to seamlessly track the actual start and end times for each step of a Work in Progress (WIP) Work Order operation. Users can start, pause, restart, and conclude operations, facilitating comprehensive control over the production process.

- Pause and restart capabilities: Users can pause and restart operations multiple times, with the option to charge or not charge pause durations to the work order, depending on predefined reason code settings.

- Setup and run management: Setup can only be initiated once for each operation step, while the run phase can be started, paused, resumed, and ended multiple times.

- Data recording: Consumption, production, and scrap data will be reported while the run phase is in progress. All posted data is recorded against the login user, providing accountability and traceability within the system.

- Duration calculation and posting: Setup and run durations are automatically calculated and posted to NetSuite upon completion, ensuring accurate tracking of production time.

With these enhancements, users can streamline their manufacturing processes, optimize resource utilization, and enhance overall efficiency in work order management.

Access work order instructions on Mobile devices

In the latest NetSuite Manufacturing Mobile Suite App update, factory workers can now easily access work instructions from their mobile devices. These instructions, including text, images, files, and URLs, are defined within the assembly routing, providing clear guidance for each operation. This feature ensures convenience and efficiency on the shop floor, allowing workers to view instructions directly from their mobile devices during operations. Key benefits include:

- Instruction support: Work instructions can include various multimedia elements, ensuring clarity and thorough guidance for each operation

- Mobile compatibility: The Manufacturing Mobile Suite App fully supports viewing work instructions from mobile devices, allowing users to access instructions conveniently on the shop floor

- Defined routing instructions: Instructions for each operation are defined within the assembly routing, ensuring consistency and accuracy across manufacturing processes

With this enhancement, factory workers can enhance their productivity and accuracy by having access to detailed instructions at their fingertips, ultimately contributing to streamlined operations and improved overall efficiency.

Next steps

The enhancements introduced in the NetSuite Manufacturing Mobile app with the 2024.1 release help streamline manufacturing processes and improve operational efficiency. With features such as automated inventory management, precise tracking of work order start and end times, and seamless access to comprehensive work instructions on mobile devices, manufacturers can optimize their workflows and achieve higher levels of productivity.

Whether you’re already utilizing NetSuite or considering its implementation for your manufacturing operations, these enhancements offer valuable tools to enhance efficiency and drive success. Contact Rand Group to learn more about how NetSuite can revolutionize your manufacturing processes and propel your business forward.