What to look for in a field service solution for your oil & gas business

Businesses with field service options must maintain top-notch service delivery to stay competitive in today’s environment. To streamline field service management and provide maximum value to customers while improving productivity and profitability, most organizations utilize a field service software to automate processes. When it comes to choosing a field service solution, where do you begin?

First, you make a list of all the functionality your company needs. Then rank each in the order of importance to get an idea of what to prioritize in your solution search. Each company has different needs and unique processes to accommodate, and it varies widely by industry. For oil & gas companies, their field service needs could be far different than another industry just due to the specific equipment used in operations. You could be operating in multiple states or countries, requiring your company to keep track of different regulations in each location when it comes to safety and environmental impact.

As with any software search, it can be a daunting process to sift through all the solutions on the market. Most field service solutions will have similar core features, but you’ll want to find the one best suited for your specific industry. Below are key features that our team of experts find most helpful for oil & gas companies to have in their field service solution to help you in your search.

Site inspections

Regular inspections of your site are key to maintaining equipment efficiency and a safe environment. Whether you are performing visual inspections, using ultrasonic techniques or radiography, you need to keep up to date with inspections. A field service solution should automate work order creation for each inspection, for every piece of equipment, and for any type of inspection, plus capture and store all necessary information in an organized matter. Additionally, its key for your field service solution to be compatible on a mobile device or tablet so that inspections can be done electronically. Gone are the days of checklists on a clipboard then manually entering data to a system.

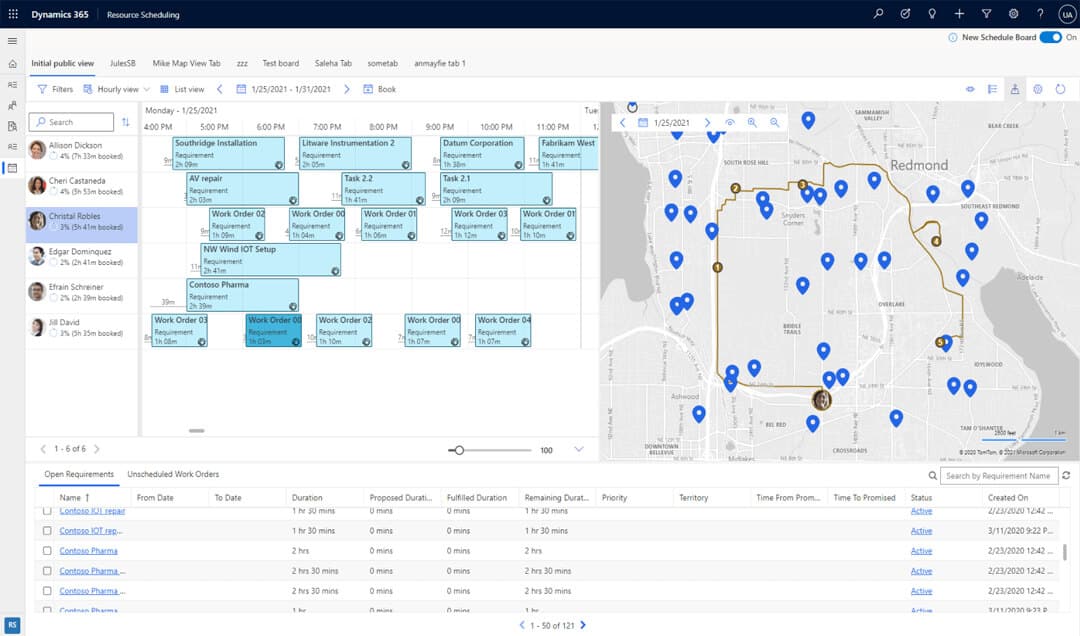

Resource routing and scheduling

A field service solution should help you match and route the most appropriate technician to each work order. It will keep track of resource locations, skill sets, and availability to help you easily determine not only who is closest to the job, but also who is available and has the right skills to complete the task at hand. Some solutions, such as Dynamics 365 Field Service, have advanced resource scheduling tools that offer suggestions and automate routing based on pre-defined rules you configure.

Parts inventory management

In order to facilitate asset management, it’s important to have inventory management of the parts your technicians use on a daily basis. The system will record each time a technician takes or uses a part, which keeps a real-time record of your stock. Ideally you can also automatically send an alert once the inventory for a certain part reaches a predetermined level, so you always know when you need to order more. Moreover, many systems integrate analytics with their inventory software to create demand forecasts. This gives office staff insight into which parts are used the most and when they should expect to reorder.

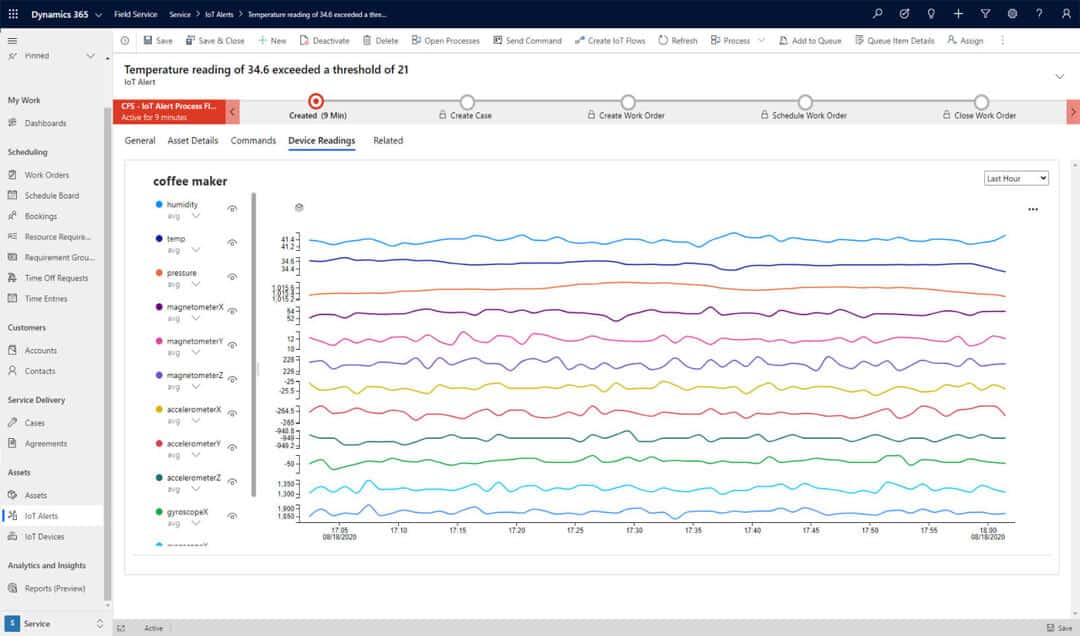

Remote equipment monitoring

As an oil & gas company, you have valuable equipment in various locations all with different maintenance requirements. Your field service solution should make it easy to monitor equipment remotely through connected sensors to reduce technician field visits. A sensor with connected capabilities can be placed on the equipment to collect status reports. The sensor then sends the data in real-time to your software where it is matched with its equipment record and appropriate site. You can also set up rules to alert technicians of any issues, and automatically schedule a technician visit when a problem is detected. Remote equipment monitoring saves time, and reduces costs by detecting problems immediately and even predicting issues before they occur.

Next steps

For oil & gas businesses looking for a cloud-based, connected field service solution, Microsoft Dynamics 365 Field Service is a top choice that includes all the features discussed above. Dynamics 365 Field Service uses intelligent IoT and machine learning capabilities to enable proactive field service operations, effective resource scheduling, and the ability to fix problems the first time.

Rand Group is a certified Microsoft gold partner with over 20 years of experience implementing and supporting custom solutions for clients – including numerous oil & gas organizations. Contact our team of solution architects today to learn more about how Dynamics 365 Field Service can transform your field operations.