AI-enabled ERP and CRM solutions for discrete manufacturing

Discrete manufacturers understand the mounting pressure for more innovative and better-quality products, shorter product lifecycles and stricter compliance to safety and environmental regulations. Rand Group delivers AI-enabled ERP and CRM solutions built on Microsoft Dynamics 365, NetSuite, and Sage. Our systems help manufacturers streamline production, enhance visibility, and make data-driven decisions that drive efficiency, innovation, and long-term growth.

Run a productive, fast moving operation with a customized ERP solution

Discrete manufacturers that adopt a tailored ERP solution have the opportunity to increase production throughput, reduce production delays, cut costly inefficiencies, and improve the performance of their machinery and industrial assets. Rand Group’s industry and ERP experts combined with the power of Microsoft, NetSuite, and other leading technologies deliver connected systems with automated process and data flows throughout your manufacturing operation.

Rand Group is your long-term partner to help you address industry challenges such as improving agility, managing warranties, balancing changing supply and demand, reducing time to market, and more. We have been serving discrete manufacturing clients – from industrial goods and building materials to steel and oilfield machinery – since 2003, and are a certified Microsoft gold partner and Oracle NetSuite Solution Provider.

Deliver the perfect order each time

Automate order promising, allocation, orchestration, and execution processes so you can efficiently fulfill orders based on global inventory availability and business rules. Manage all of your orders in a single system with integrated order-to-cash processes.

Create a streamlined product lifecycle

Develop a shared and singular version of truth for all item master data. Implement an organized and structured method for handling product changes to reduce delays and go-to-market faster.

Use data to make planning decisions faster

Infuse your planning process with supply chain, sales, and marketing pipeline data to improve demand forecasting so that you can make smarter, better decisions about the future.

Proven results

%

Improvements in inventory returns

%

Reduction in operational costs

%

Improvements in internal schedule compliance

Case Study

See how a cabinetry manufacturer modernized operations with Microsoft Dynamics 365 Business Central

Partnering with Rand Group, they transitioned from Dynamics GP to the cloud. Migrating helped them streamline workflows, improve real-time reporting, and create a scalable foundation to support continued growth and operational efficiency.

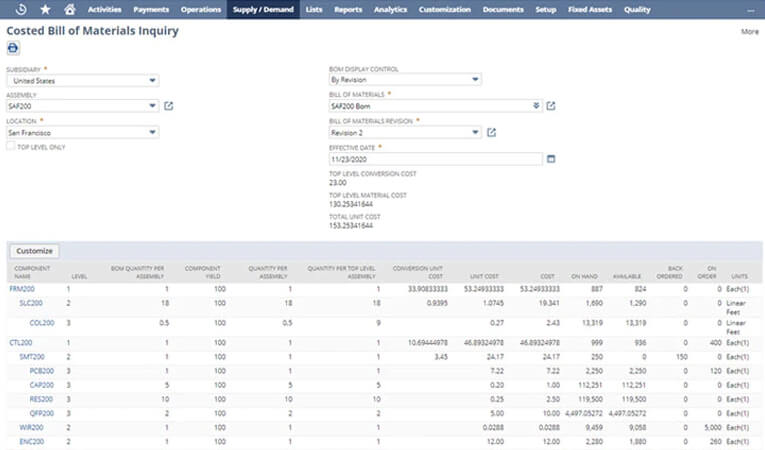

Customize multiple bill of materials

With a discrete manufacturing ERP, your team will have the ability to manage the complexity of various bill of materials (BOMs) in a single platform. Version control allows you to make ongoing changes to an item and set up different configurations based on the circumstance or location. You can also set expiration dates and phase out old components so that new components can be produced or bought.

Microsoft and NetSuite ERP solutions have the following capabilities to manage your BOMs:

- Create, edit, and copy BOMs, BOM versions, and routes

- Check for errors, including circularity

- View and verify sites the BOM versions are assigned

- Add, edit, and print BOM and BOM lines

- Run a cost or sales price calculation for a product variant

- Approve and activate product changes

Production configuration and scheduling for discrete manufacturing

Modern manufacturers must adapt quickly to customer-specific requirements while maintaining efficient production schedules. With AI-enabled ERP solutions, you can build product configuration models faster and automatically schedule production based on real-time supply and demand. This flexibility supports configure-to-order scenarios, reduces inventory costs, and ensures resources are used effectively across every operation.

Key capabilities include:

- Creating dynamic product configuration models with templates and visual overviews.

- Automating scheduling based on material availability, resource capacity, and production priorities.

- Splitting and sequencing production orders to meet delivery timelines.

- Assigning operations to resources or resource groups for maximum efficiency.

- Managing scrap and improving throughput with data-driven insights.

AI-driven modern ERP and CRM from Rand Group

Our leading ERP and CRM platforms from Microsoft Dynamics 365, NetSuite, and Sage, already include powerful AI capabilities. But realizing their full potential requires expert setup and optimization. We help manufacturers implement and fine-tune AI tools like Dynamics 365 Copilot, NetSuite AI, and Sage AI to drive efficiency, agility, and innovation.

Key capabilities include:

- Smarter forecasting: Predict demand and optimize production planning.

- Production optimization: Use intelligent insights to streamline scheduling and resource allocation.

- Predictive maintenance: Monitor equipment performance to prevent costly downtime.

- Conversational assistance: Simplify reporting and routine tasks with AI-powered tools.

With AI-enabled ERP and CRM solutions from Rand Group, discrete manufacturers can operate more intelligently, respond faster to change, and stay ahead of the competition.

White Paper

8 new ways manufacturers can tackle the talent shortage

Manufacturing is an industry that requires a high percentage of workers with specialized skills, and a qualified talent shortage has been brewing since before the pandemic. There is no singular or simple solution for this problem, but there are immediate steps and long-term strategies manufacturers can take to mitigate the skills gap and help find and retain talent.

Industry-tailored solutions for discrete manufacturing offered by Rand Group

Rand Group is proud to offer a variety of ERP solutions built by Microsoft and NetSuite to transform the way you run your manufacturing operations. Our team will help you evaluate and select the best solution for your discrete manufacturing business, then implement and customize it based on your specific processes. Explore Microsoft and NetSuite solutions below based on your organization’s unique needs.

Dynamics Manufacturing

Dynamics 365 Manufacturing is a collection of end-to-end cloud solutions that help securely connect people, assets, and business processes. It is designed for midsize to large organizations with complex manufacturing operations.

Business Central for Manufacturing

Dynamics 365 Business Central is a cloud-based business management solution for small and midsize organizations that automates and streamlines processes, plus has dedicated capabilities for managing manufacturing processes.

NetSuite for Manufacturing

SuiteSuccess Manufacturing by NetSuite is a unified suite to support manufacturing needs including forecasting, supply chain, shop floor scheduling and capacity monitoring, work order management, procurement, and fulfillment.

Why partner with Rand Group?

Flexible & scalable solutions

From ERP modernization and AI-driven forecasting to custom applications, we deliver technology designed to scale with your manufacturing business. Our approach ensures your systems evolve with changing market conditions, customer demands, and long-term business goals.

Proven results

With a 90% client retention rate across industries, Rand Group has built long-term partnerships by consistently delivering measurable improvements and ongoing value. Our success reflects a commitment to helping manufacturers optimize operations, strengthen supply chains, and achieve sustainable growth.

Expertise across platforms

Rand Group partners with Microsoft Dynamics 365, NetSuite, and Sage, giving manufacturers the flexibility to select the ERP system that best fits their business goals. With deep expertise across multiple platforms, we provide unbiased guidance, tailored recommendations, and proven implementation strategies that set your organization up for long-term success.

Industry focus

With decades of experience supporting manufacturers, we understand the challenges of complex supply chains, shifting customer demand, labor shortages, and strict quality requirements. We combine technical proficiency with industry insight to deliver ERP and CRM solutions that address real-world manufacturing pressures.