Inventory management in Dynamics 365 Supply Chain Management

Effective inventory management is a key advantage in modern supply chains. Dynamics 365 Supply Chain Management, a key component of the broader Dynamics 365 Finance and Operations portfolio—provides enterprises with end-to-end visibility and control across procurement, production, distribution and warehousing. Inventory management, in particular, plays a vital role: it ensures that the right products are available in the right place, at the right time, and at the right cost. This blog will explore what inventory management means in the context of Dynamics 365 Supply Chain Management, why it matters, what capabilities it offers, and how you can transform your inventory management journey with Rand Group.

What is inventory management in Dynamics 365 Supply Chain Management?

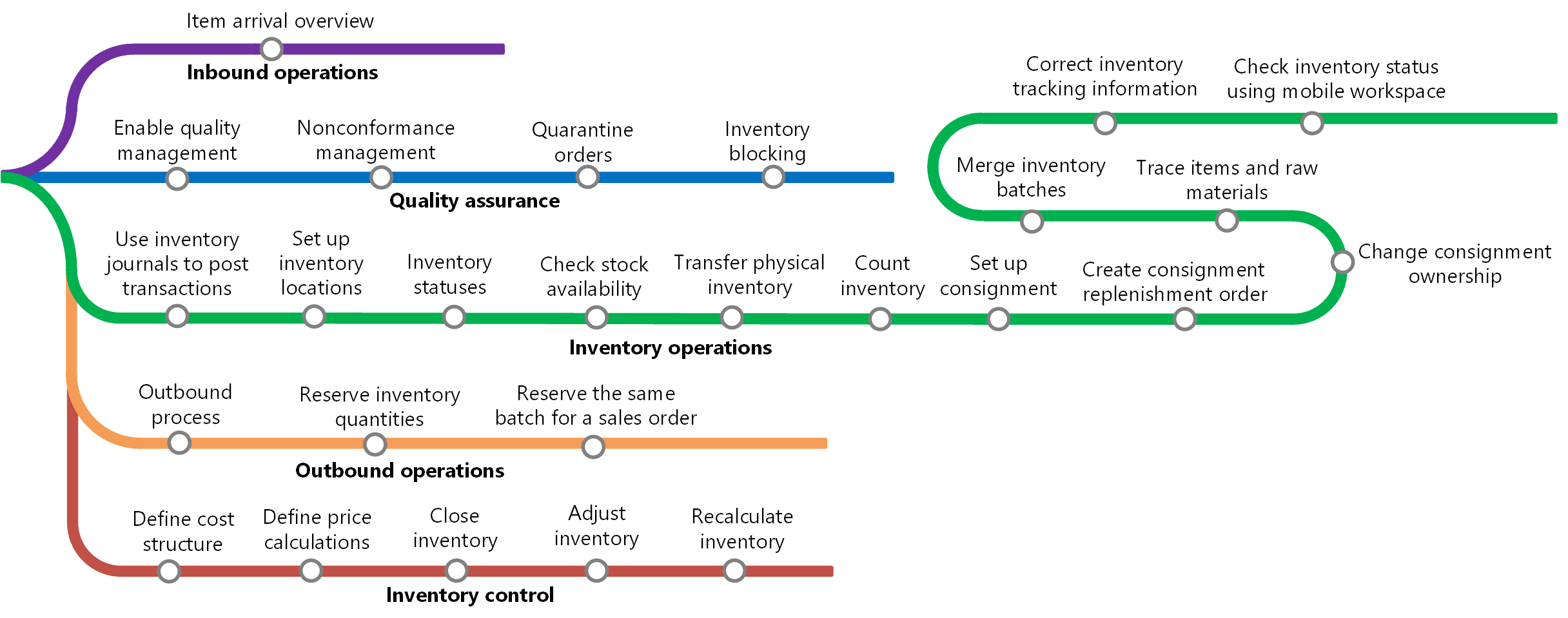

Inventory management within Dynamics 365 Supply Chain Management is the set of processes, technologies and controls that govern the flow of goods into, through and out of your organization. The inventory management module enables organizations to perform inbound operations, quality assurance, inventory activities, outbound operations, and inventory control. Put simply: when a purchase order arrives, when goods are received, when stock is counted or adjusted, when items are shipped out, and when you monitor stock levels and value—you are engaging inventory management. These capabilities sit within the broader supply-chain ecosystem and connect to warehouse management, production, procurement, and sales.

What are the benefits of inventory management in Dynamics 365 Supply Chain Management?

When your enterprise uses the inventory management capabilities of Dynamics 365 Supply Chain Management, you can achieve benefits such as:

- Improved visibility: Real-time tracking of on-hand quantities, expected receipts, reservations and availability helps you know exactly what inventory you have and where it is.

- Reduced costs and better cash-flow: By optimizing inventory levels (avoiding over-stocking and stock-outs) you free up working capital and reduce carrying costs.

- Greater agility and responsiveness: With streamlined inbound/outbound flows, and links to production and warehousing, you can respond faster to market changes.

- Enhanced quality and compliance: Built-in quality assurance and control capabilities help you ensure product integrity and reduce returns or non-conforming inventory.

- Strategic decision-making: With analytics, reporting, and unified inventory data, you can use inventory management as a driver for operational improvement rather than just a cost centre.

Ready to optimize your inventory?

Discover how Rand Group can help you unlock real-time visibility, reduce over-stocking and align inventory with business strategy using Dynamics 365 Supply Chain Management.

Capabilities of inventory management in Dynamics 365 Supply Chain Management

Dynamics 365 Supply Chain Management offers a comprehensive set of tools to control, track, and optimize every aspect of inventory—from inbound logistics to cost control and AI-driven forecasting. Below is an overview of some core capabilities and how they support inventory management:

Inbound operations

Gain full control over the receipt of goods and ensure that materials are accurately recorded and efficiently processed as they enter your supply chain. This capability streamlines the flow of inbound shipments, reducing errors and improving visibility from supplier to warehouse.

Capabilities include:

- Creation of inbound loads or shipment records to represent expected deliveries.

- Receipt registration of goods via mobile or web interface when loads arrive at dock.

- Posting product receipt transactions to inventory ledger, updating on-hand quantities.

- Integration with warehouse and transportation management to ensure efficient arrival, staging and put-away.

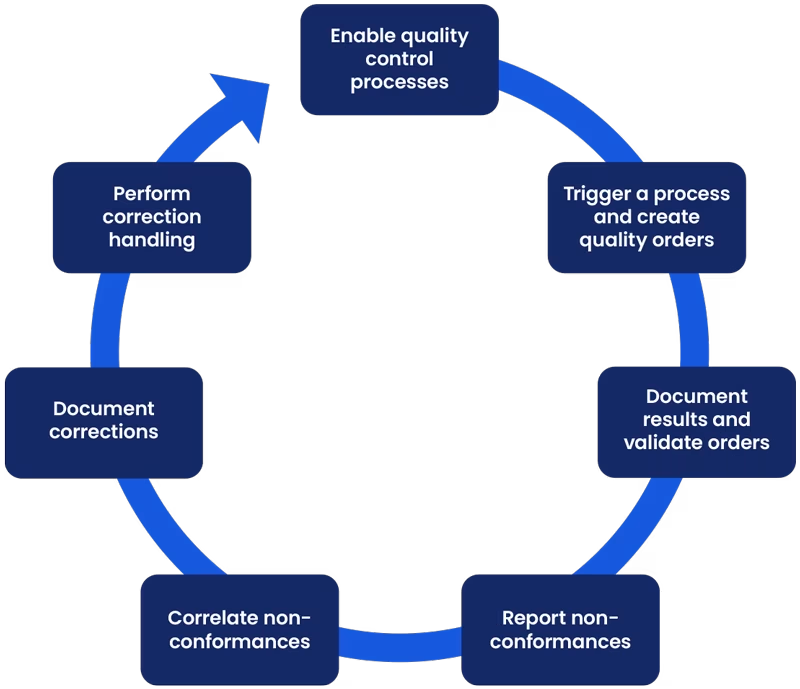

Quality assurance

Maintain product quality and compliance standards across your inventory processes to safeguard brand reputation and customer satisfaction. The system allows businesses to integrate inspection and testing directly into warehouse workflows, ensuring every item meets specifications before it’s made available for sale or production.

Capabilities include:

- Define quality associations that trigger automatic quality orders when specific events occur (e.g., purchase registration).

- Set up item sampling rules (by quantity, load, license plate, etc.) to determine how many items or loads are subjected to quality checks.

- Integrate quality workflows into warehouse receiving processes: move items to quality-control locations, approve or reject, then direct put-away or return.

- Analyze quality-performance KPI data (non-conformance trends, corrective tasks) to refine processes.

Inventory activities

Simplify daily inventory tasks such as adjustments, transfers, and counting to maintain accurate stock records across multiple locations. With centralized data and automation, businesses can improve accuracy, reduce manual errors, and ensure every transaction reflects in real time across the entire organization.

Capabilities include:

- Maintain on-hand lists with filters by product, location, dimensions; view physical inventory, reserved inventory, available quantities, on-order quantities, etc.

- Configure storage, tracking and dimension parameters to support granularity (e.g., serial numbers, batches, location, license plates).

- Perform inventory journal entries for adjustments, transfers, reclassifications; initialize stock levels and reconcile stock differences.

- Set up inventory policies and item-model groups to drive consistent rules for valuing and managing different items.

Outbound operations

Enhance order fulfillment by managing outbound shipments with greater precision and speed. This capability connects inventory availability with order processing and logistics, ensuring customers receive products on time while maintaining optimal stock levels.

Capabilities include:

- Reserve available inventory for sales orders, transfer orders or production demands.

- Manage shipments, load building, dispatch and delivery planning via integration with transportation management.

- Handle returns, backorders and replenishment to ensure service-level targets are met.

Inventory control

Gain real-time visibility and control over your inventory value, cost, and performance to support accurate decision-making. With integrated costing, visibility add-ins, and compliance tools, this capability ensures financial accuracy and operational consistency across every inventory movement.

Capabilities include:

- Use the Inventory Visibility Add‑in micro-service to track on-hand inventory in real time across multiple channels, sources and locations.

- Provide available-to-promise (ATP) information, soft reservations and global stock visibility to avoid overselling.

- Manage costing methods (FIFO, weighted average, standard cost, etc.) and perform inventory close processes to settle transactions and post to the general ledger.

- Enable governance over inventory movements, audit trails, status tracking and dimension modelling to align with compliance and reporting needs.

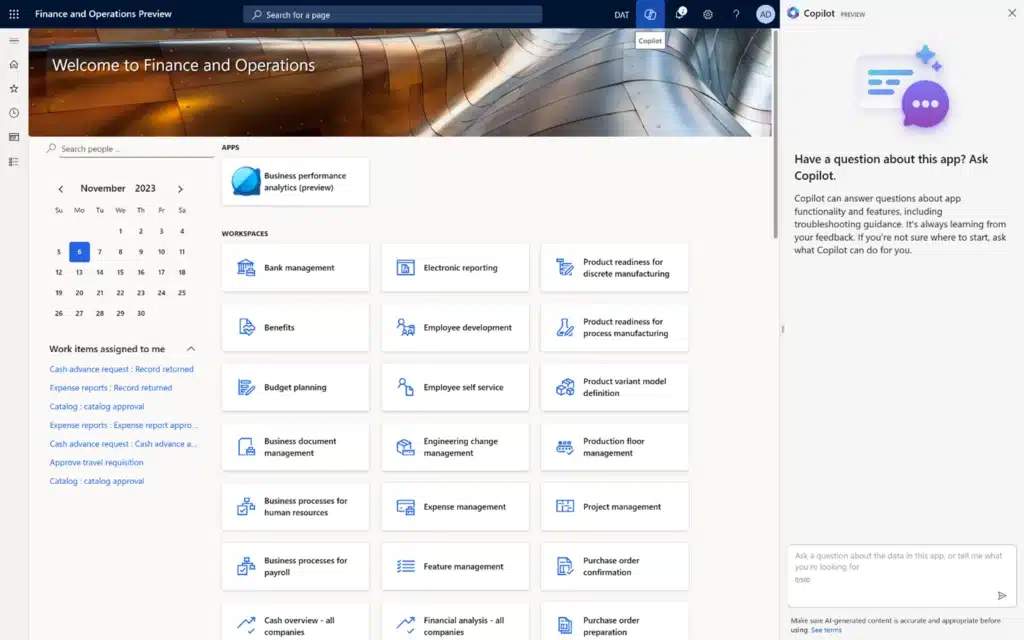

AI and Copilot insights

Leverage artificial intelligence and Microsoft Copilot to make inventory management more proactive and data-driven. These intelligent tools help predict demand fluctuations, recommend replenishment actions, and automate manual tasks—empowering teams to focus on strategic decision-making rather than routine operations.

Capabilities include:

- Use Copilot in Dynamics 365 Supply Chain Management to receive AI-generated recommendations for replenishment, demand forecasting, and anomaly detection.

- Analyze historical data to predict shortages, suggest reorder quantities, and optimize stock levels.

- Automate repetitive inventory tasks, such as updating safety stock levels or generating purchase suggestions, based on real-time trends and business rules.

- Enable natural language prompts through Microsoft Copilot to quickly retrieve insights—for example, “Show me inventory at risk this week” or “Suggest replenishment for Item A123.”

Transform your inventory management journey with Rand Group

At Rand Group, we help manufacturing and distribution organizations harness the full power of Dynamics 365 Supply Chain Management’s inventory capabilities. Whether you’re transitioning from an older ERP system, optimizing existing inventory processes, or preparing for digital supply chain transformation, our team brings deep industry experience and Microsoft ecosystem expertise.

From initial strategy and implementation to ongoing training and support, Rand Group ensures your team is equipped to make the most of your system. Our consultants work side by side with your organization to define clear business goals, configure the right capabilities, and optimize your inventory flows for long-term success. The result is measurable impact, reduced carrying costs, improved fill rates, and stronger cash flow—all backed by a trusted partner committed to your growth.

Frequently Asked Questions

- What kinds of businesses benefit most from inventory management in Dynamics 365 Supply Chain Management?

Companies with multi-site distribution, manufacturing operations, or complex demand and supply flows benefit most—especially if they require tight inventory control, real-time visibility and integration across procurement, production and warehousing. - How does inventory management in Dynamics 365 differ from basic ERP stock modules?

Unlike basic stock modules, Dynamics 365 Supply Chain Management’s inventory management supports end-to-end inbound/outbound, quality assurance, dimension modelling, real-time visibility (via Inventory Visibility), and deep integration with warehouse, manufacturing and logistics. - Does Dynamics 365 Supply Chain Management integrate with other Microsoft applications?

Absolutely. Dynamics 365 Supply Chain Management seamlessly integrates with Microsoft Power BI for analytics, Power Automate for workflow automation, and Microsoft Teams for collaboration. This unified ecosystem allows your teams to make faster, data-driven decisions and maintain real-time visibility across your supply chain. - Are there any AI or Copilot features available in Dynamics 365 Supply Chain Management for inventory management?

Yes. Microsoft Copilot introduces AI-driven insights and automation across the Dynamics 365 Supply Chain Management suite. In inventory management, Copilot helps forecast demand, suggest reorder points, and detect anomalies—empowering users to make proactive, data-driven decisions that improve accuracy and reduce manual effort.

Next steps

Inventory management is no longer just a back-office function—it’s a strategic lever that impacts customer satisfaction, working capital and operational agility. With Dynamics 365 Supply Chain Management, organizations gain the tools to move beyond reactive inventory practices toward proactive, optimized inventory flows. At Rand Group, we stand ready to guide you on that journey—from discovery and design through deployment and optimization. If you’re ready to gain control of your inventory, reduce costs and elevate service levels, contact us today and make inventory management a competitive advantage.