ERP software for process manufacturing

The right process manufacturing ERP software makes it easier to meet customer needs with an optimal balance of flexibility and efficiency to create the formulas you want to test and produce within a solid compliance framework. An ERP solution built by Microsoft and delivered with customizations to your business by Rand Group can transform your day-to-day operations and provide deeper insights.

Do more with a single solution to manage your process manufacturing operations

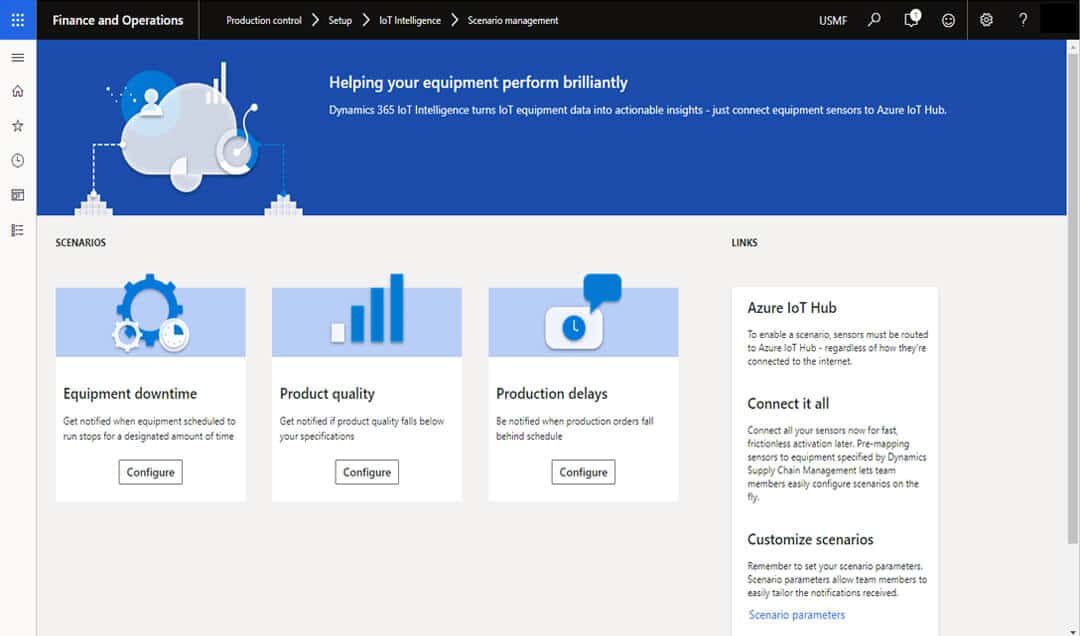

Process manufacturers that partner with Rand Group for business solutions have increased production throughput, cut production delays, eliminated costly inefficiencies, and boosted the performance of their machinery and industrial assets. Our industry and ERP experts combined with the power of Microsoft technologies deliver connected systems with automated process and data flows throughout your operation and supply chain relationships.

Rand Group is your long-term partner to help you address industry challenges such as batch order balancing, lot characteristics inheritance, scheduling, formula management, managing purchase prices based on potency, and more. We have been serving clients in the chemicals and food & beverage manufacturing industries since 2003, and are a certified Microsoft gold partner.

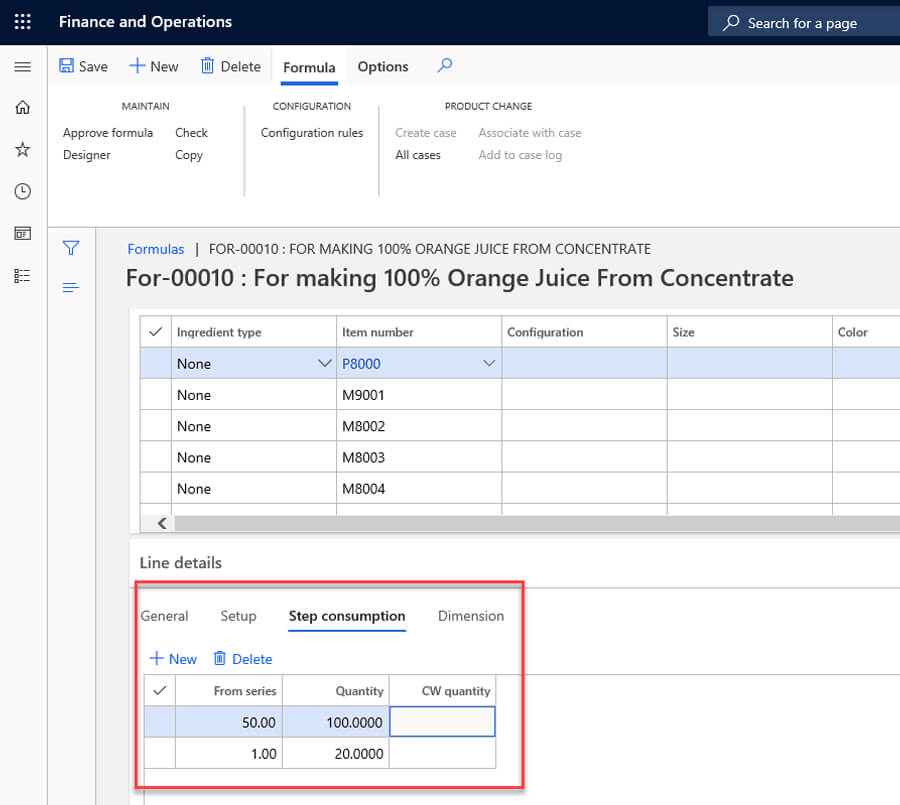

Formula management

Easily manage complex formulas by volume or weight while maintaining quality, plus keep track of co-products and by-products.

Batch order sequencing

Track lot requirements, and leverage production statistics reporting, and specification management tools to gain the control and predictability with production.

Manage commodity pricing

A manufacturing-tailored ERP can automatically adjust product prices based on daily, weekly, and monthly fluctuating commodity prices.

White Paper

Four pillars of the digital supply chain

A digital twin strategy can be used to model complex processes that combine physical, digital, and process components—which makes it ideal for modernizing supply chain management and providing a new level of control tower functionality to the business. In this whitepaper, learn more about a digital twin strategy and four pillars to set your supply chain up for long-term success in the digital era.

White Paper

Four pillars of the digital supply chain

A digital twin strategy can be used to model complex processes that combine physical, digital, and process components—which makes it ideal for modernizing supply chain management and providing a new level of control tower functionality to the business. In this whitepaper, learn more about a digital twin strategy and four pillars to set your supply chain up for long-term success in the digital era.

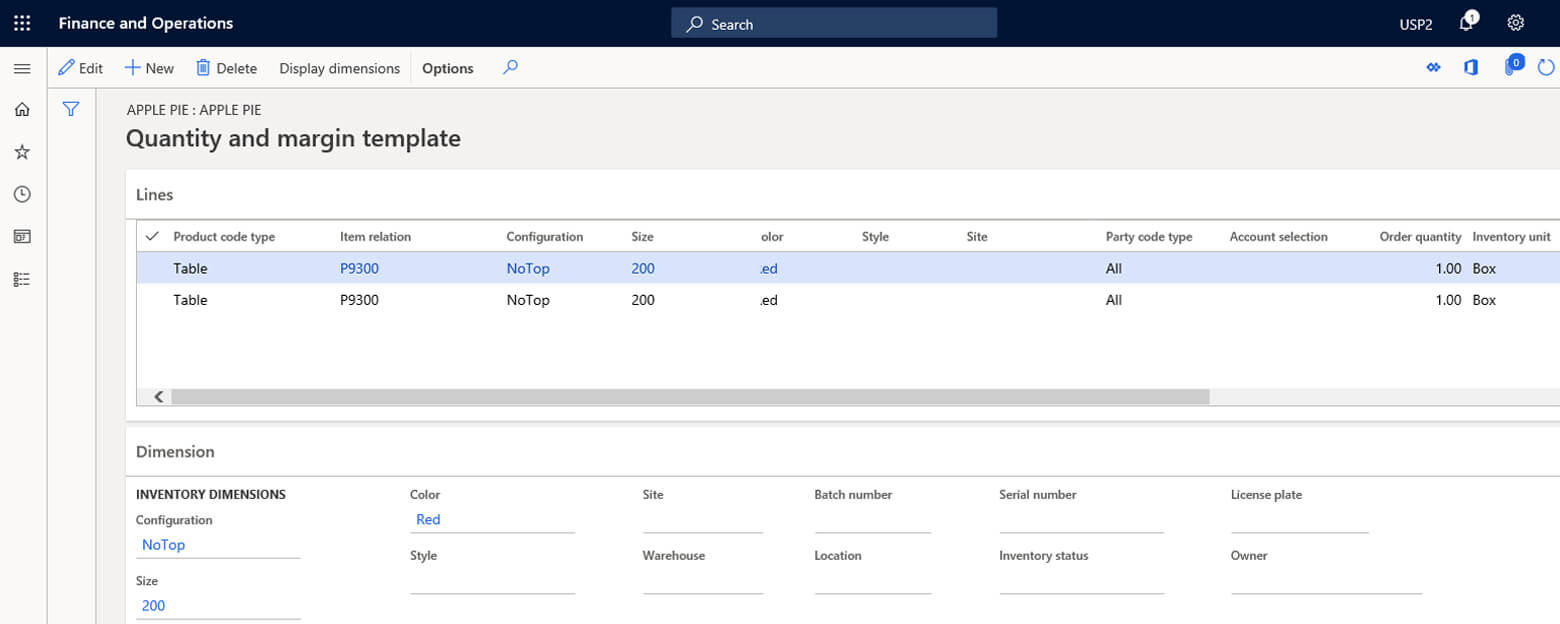

Configure formulas and manage co-products and by-products

Managing formulas is a cornerstone task for process manufacturers. In an ever-changing business landscape, you need the ability to easily maintain multiple formula versions based on each customer, maintain quality control and compliance, and manage co-products and by-products.

Essential formula management tasks made possible with Dynamics 365 include:

- View real-time costs when formulas are updated

- Manage the complete cost of formulas to include labor, overhead, and planned cost increases of raw materials

- Identify standard quality-control tests and values for individual formulas

- View historical quality-control values by formula production

Manage commodity pricing and compliance requirements

In manufacturing, purchase price fluctuations of the commodities used to create a good impact the cost and sales price of the finished good. For the sale of the good to remain viable, the sales price of the finished product must be adjusted regularly with respect to the pricing fluctuations in the commodity market. Dynamics 365 can automatically adjust sales prices based on commodity prices.

Product compliance is also key, especially for chemicals, food & beverage, and pharmaceutical manufacturers that need to restrict and regulate shipments to specific countries or regions.

Configure batch attributes

Often times customers will ask for specific requirements where you must define batch attributes such as the fat content of milk to make a cheese or viscosity of a paint. Then, after a quality check, the finished goods must meet the value or range of values from batch attributes.

With Dynamics 365 you can:

- Assign and reserve batch attributes

- Manage products with active ingredients

- Set ingredient types

- Reserve batch attributes on sales orders

Rand Group’s industry-tailored solutions for process manufacturing

Rand Group offers a variety of manufacturing-tailored solutions built by Microsoft to transform the way you run your operations. Our team will help you evaluate and select the best solution for your process manufacturing business, then implement and customize it based on your specific processes.

Dynamics 365 Manufacturing

Dynamics 365 for Manufacturing is a collection of end-to-end manufacturing cloud solutions that help securely connect people, assets, workflow, and business processes for midsize to large organizations with complex manufacturing processes.

Dynamics 365 Guides

Dynamics 365 Guides is a mixed-reality application for Microsoft HoloLens that empowers operators to learn during the flow of work using holographic instructions to get jobs done faster, minimize hours, and improve skills.