Overview of warehouse management in Dynamics 365 Finance & Supply Chain Management

Efficient warehouse management is critical for businesses to meet customer demands and operate profitably. Even a single missed scan or a delayed shipment can disrupt operations and erode customer trust. Microsoft Dynamics 365 Supply Chain Management (D365 SCM), part of the broader Dynamics 365 Finance and Operations suite, includes a robust Warehouse Management module that helps organizations streamline every aspect of warehouse operations—from receiving inventory to shipping orders—within a unified ERP system. This integrated approach transforms warehousing from a series of isolated tasks into a coordinated, data-driven process. The result is clearer workflows, more reliable inventory levels, and the ability to fulfill orders accurately and on time.

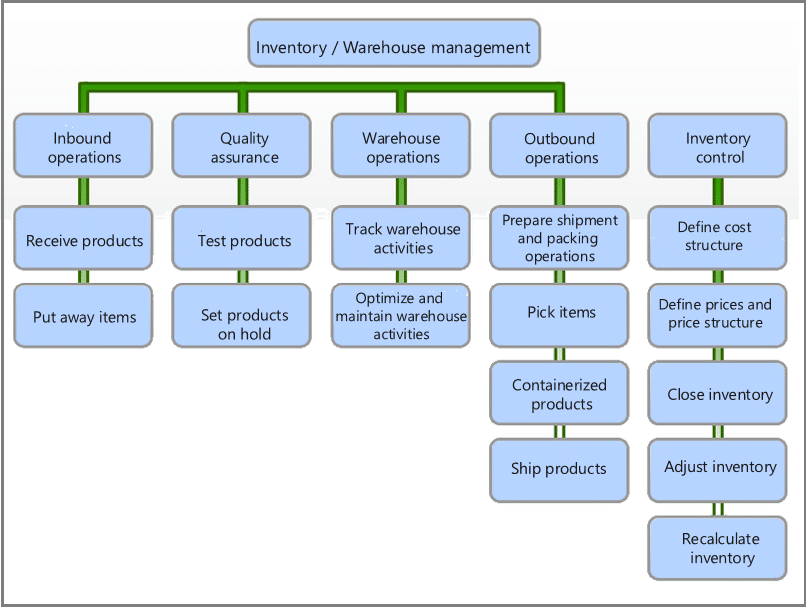

What is warehouse management in Dynamics 365 Supply Chain Management?

At its core, warehouse management in Dynamics 365 Supply Chain Management is a comprehensive set of tools for controlling, automating, and monitoring warehouse processes. From receiving shipments and putting goods away to picking orders, packing, and shipping, the module orchestrates every movement inside the warehouse.

Unlike standalone warehouse management systems (WMS), D365 SCM is fully integrated into one Microsoft ERP system. This means warehouse data is not a separate silo—it directly informs purchasing, sales, finance, and production. When a supplier delivers materials, purchase orders trigger automated receiving workflows. When a customer order ships, the system updates inventory and records the cost of goods sold in finance immediately. This eliminates duplicate entry, reduces delays, and provides a single source of truth.

The module also includes advanced functionality such as wave and batch picking, location directives, quality control integration, cycle counting, mobile workflows, and even AI-driven insights with Copilot. For manufacturers, it connects with production orders to issue materials and receive finished goods seamlessly. For distributors, it enables multi-warehouse and multi-site coordination with real-time visibility.

What are the benefits of warehouse management in Dynamics 365 Supply Chain Management?

Implementing the warehouse management module in Dynamics 365 SCM can deliver significant business benefits. By streamlining warehouse operations and unifying data, organizations often see improvements in efficiency, accuracy, and agility. Below are some of the key benefits:

- Real-time visibility: Every warehouse transaction updates inventory instantly, giving managers accurate views of stock levels and order progress. Alerts notify procurement before shortages occur, enabling proactive decision-making.

- Improved accuracy: Barcode scanning, automated data capture, and guided workflows reduce errors like mis-picks or duplicate records. Each movement is validated, ensuring inventory reflects reality.

- Higher efficiency: Automation accelerates tasks such as put-away, picking, and replenishment. The system directs workers step by step, boosting throughput and speeding up onboarding.

- Easier training:The mobile app provides simple, guided workflows so even seasonal staff can become productive in hours. This reduces supervisor burden and ensures consistency across shifts.

- Compliance and traceability: Dynamics 365 SCM records every transaction, supporting batch and serial tracking for strict industries like pharma and food. In case of recalls, affected products can be identified and located quickly.

- Data-driven insights: Warehouse data flows into Power BI dashboards, helping managers monitor KPIs like order accuracy and fulfillment times. Insights highlight bottlenecks and drive continuous improvement.

Dynamics 365 Supply Chain Management licensing & pricing guide

Understand how Dynamics 365 Supply Chain Management licensing works and what it means for your business. Our guide breaks down pricing structures, user types, and license options—helping you choose the most cost-effective plan for your organization’s needs. Download the guide to get started.

Capabilities of warehouse management in Dynamics 365 Supply Chain Management

Dynamics 365 SCM warehouse management module comes with a rich set of features and capabilities designed to handle both basic and advanced warehousing needs. Below is an overview of some core capabilities and how they support warehouse operations:

Inbound receiving & put-away

Receiving is the first opportunity to ensure accuracy in inventory. Dynamics 365 SCM automates this process by generating receipt records as soon as shipments arrive. Workers scan items or pallets, and the system creates put-away tasks based on predefined rules.

For example, fragile items can be routed to specialized storage, while fast-moving SKUs may be placed near the picking area for quick access. If goods require inspection, the system automatically routes them to quality control before release. By guiding workers with handheld devices, Dynamics 365 SCM ensures that products are stored correctly the first time.

Capabilities include:

- Reduced errors during receiving

- Optimized warehouse space usage

- Built-in quality control processes

Inventory storage & control

Once goods are in the warehouse, keeping them organized is essential. Dynamics 365 SCM provides complete control over where items are stored and their status. Managers can define zones, aisles, racks, and bins, and the system enforces these rules in real time.

Inventory statuses—such as available, damaged, or on hold—provide clarity on which items are ready for use or shipment. For traceability, the system supports batch and serial tracking, ensuring businesses can comply with industry regulations.

Automated replenishment keeps picking locations stocked by transferring goods from bulk storage when levels run low. For example, when a pick bin falls below a set threshold, the system automatically creates a replenishment task, preventing delays in order fulfillment.

Capabilities include:

- Complete visibility into stock locations

- Accurate inventory statuses and traceability

- Automated replenishment to avoid disruptions

Order picking & packing

Order fulfillment is where accuracy and speed matter most. Dynamics 365 SCM supports multiple picking methods—wave, batch, and cluster—so businesses can choose the best approach for their operations. Workers are guided through optimized routes on handheld devices, minimizing travel time and reducing errors.

Packing is equally streamlined. Containerization tools suggest the best way to pack items based on size and weight. Labels, packing slips, and shipping documentation are generated automatically. This ensures customers receive their orders quickly, correctly, and in good condition.

Capabilities include:

- Increased picking speed and accuracy

- Reduced errors in order assembly

- Optimized packing for reduced shipping costs

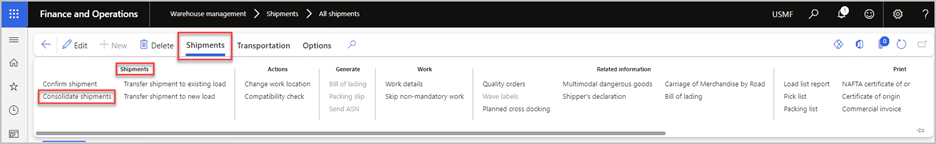

Shipping & distribution

Outbound logistics connects the warehouse to customers. Dynamics 365 SCM manages shipment staging, scheduling, and carrier integration directly within the ERP system. Shipping documents such as bills of lading and labels are generated automatically, reducing administrative overhead.

Cross-docking enables products to bypass storage and go directly from receiving to shipping when needed urgently. This is particularly valuable for backordered items or high-demand products. Integration with Transportation Management provides additional tools for route optimization and carrier rate shopping.

Capabilities include:

- Faster outbound processes

- Reduced handling with cross-docking

- Better cost control through carrier integration

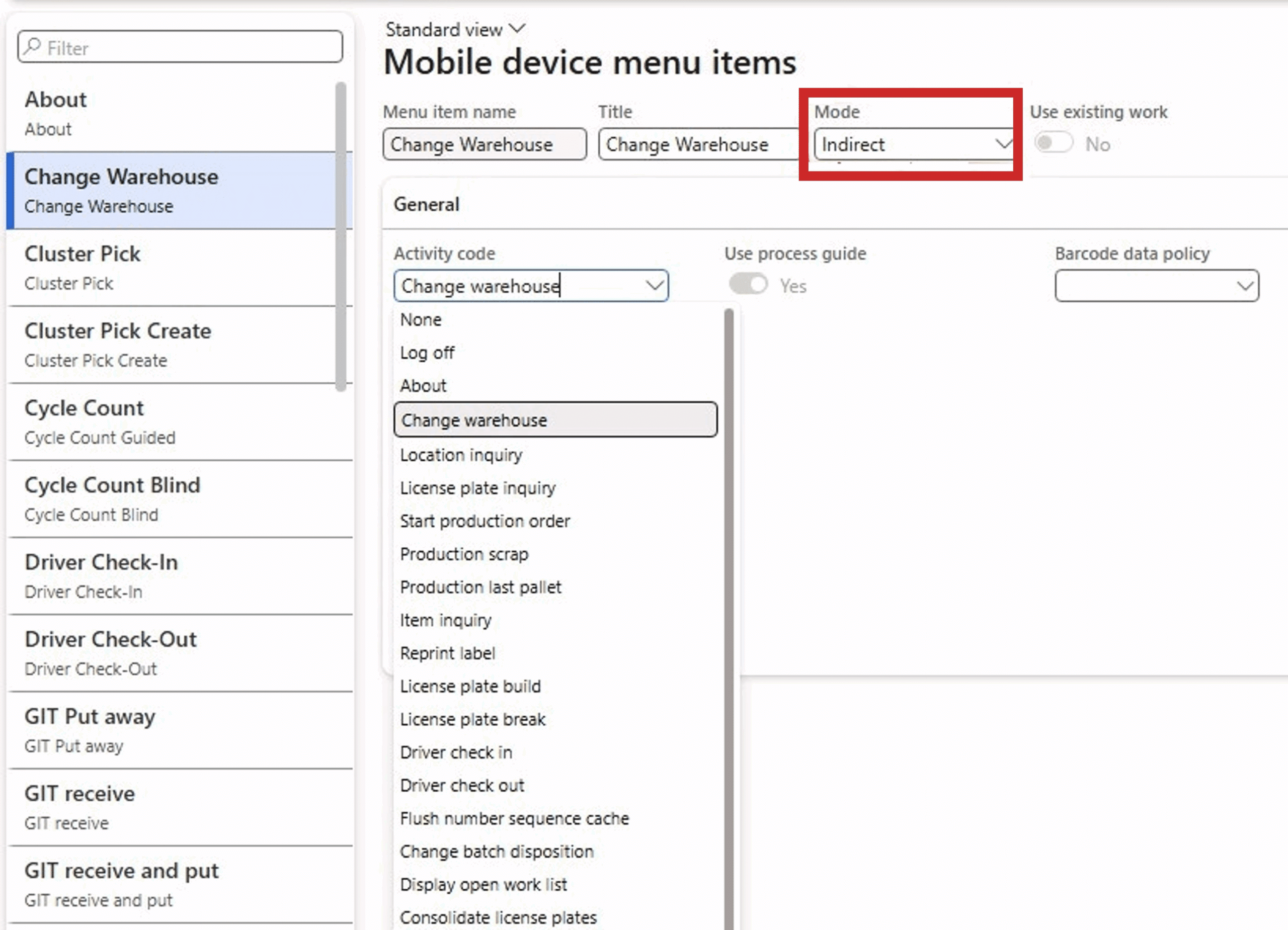

Mobile devices & barcoding

The D365 Warehouse Management mobile app allows workers to complete tasks on handheld devices, improving efficiency and accuracy. Each task—receiving, picking, counting, or shipping—is guided by step-by-step prompts.

Barcoding and RFID integration ensure that every transaction is captured correctly. For example, scanning a pallet ID records its entire contents in the system, while location barcodes ensure goods are placed in the right bin. On-demand label printing adds flexibility, allowing workers to generate barcodes as needed.

Capabilities include:

- Faster, paperless workflows

- Reduced training time for new staff

- Accurate, real-time data capture

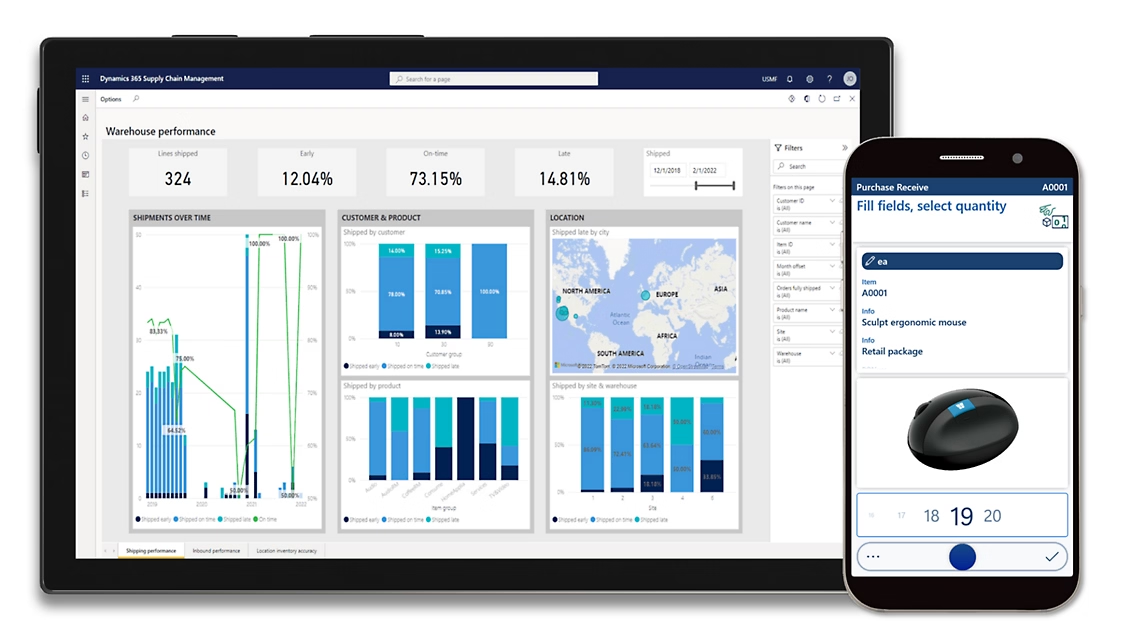

Reporting & analytics

Modern warehouses generate massive amounts of data, but without the right tools, that information can be difficult to act on. Dynamics 365 turns warehouse data into actionable insights by connecting directly to reporting and analytics tools like Power BI. Managers can track KPIs such as order accuracy, fulfillment times, inventory turnover, and space utilization in real time.

Analytics go beyond static reports—interactive dashboards highlight bottlenecks, trends, and opportunities for improvement. For example, if a particular zone in the warehouse consistently slows down picking, reports can flag the issue, prompting a reorganization of product placement. Predictive analytics can also surface patterns, such as seasonal demand spikes, allowing businesses to prepare in advance.

Capabilities include:

- Real-time dashboards for key warehouse KPIs

- Interactive analytics to uncover bottlenecks and trends

- Predictive insights to anticipate demand and optimize operations

- Role-based reporting tailored for different users

Advanced workflows & automation

Complex warehouses benefit from automation. Dynamics 365 SCM supports work and wave templates that automatically generate tasks when orders are released. This ensures consistency and reduces manual oversight.

Special allocation rules, such as FEFO (first-expiry-first-out), manage perishable goods efficiently. Integration with IoT and robotics allows businesses to connect conveyor systems, automated storage, and retrieval solutions. These advanced features increase throughput, reduce labor costs, and enable large-scale efficiency.

Capabilities include:

- Automated, consistent workflows

- Support for specialized inventory needs

- IoT and robotics integration

AI & Copilot capabilities in warehouse management

Microsoft is embedding Copilot and AI-driven tools into Dynamics 365 SCM to make warehouse operations smarter and more proactive. Instead of relying only on static workflows, Copilot analyzes real-time data to provide recommendations, automate routine tasks, and surface insights to managers.

For example, Copilot can highlight bottlenecks in picking routes, flag shipments at risk of delay, or suggest labor reallocation during peak hours. It can also identify slow-moving inventory that should be re-slotted for faster picking or predict replenishment needs before stockouts occur.

AI also supports anomaly detection. If cycle counts in a specific zone reveal frequent discrepancies, Copilot can analyze historical data to identify root causes, such as poor layout or training gaps, and recommend corrective actions. Natural language queries such as “show me all orders at risk today” make insights accessible to managers without needing technical reports.

Capabilities include:

- AI-powered recommendations for efficiency gains

- Predictive insights for stockouts, delays, and bottlenecks

- Anomaly detection for improved accuracy and quality

- Natural language queries for fast, intuitive analysis

Why choose Rand Group as your Dynamics 365 partner

Implementing a sophisticated system like Dynamics 365 Finance & Supply Chain Management and tailoring the warehouse management module to your unique operations – is a journey that benefits from expert guidance. With decades of experience delivering ERP and supply chain solutions, Rand Group helps organizations unlock the full potential of Dynamics 365 SCM capabilities. Here’s what we offer:

- Industry expertise: Rand Group’s team includes warehouse and supply chain specialists who understand real-world challenges across industries. From distribution to manufacturing, we tailor Dynamics 365 to fit your workflows and industry needs.

- Proven methodology: We follow a phased, structured implementation approach that delivers quick wins and builds toward long-term success. This minimizes disruption and ensures measurable ROI.

- Training and adoption focus: Technology only delivers value when people use it effectively. We prioritize training, change management, and user adoption to ensure lasting success.

- Ongoing optimization: Warehousing evolves with business needs. Rand Group provides continuous support, monitoring, and optimization, ensuring that your Dynamics 365 solution adapts as you grow.

Unlock smarter warehouse management with Dynamics 365 Supply Chain Management

Ready to take your warehouse operations to the next level? Rand Group can help you implement Dynamics 365 Finance & Supply Chain Management to streamline processes and deliver predictive insights.

Frequently asked questions (FAQ)

- Is the warehouse management module included with Dynamics 365 Finance & Supply Chain Management, or is it a separate product?

Warehouse management is included in Dynamics 365 Supply Chain Management, which is part of the Finance & Operations suite. It’s not a separate add-on but an integrated module, so all warehouse functions work seamlessly within your ERP system. Appropriate user or device licenses are required. - Can our warehouse staff easily learn and use D365 SCM’s warehouse management tools?

Yes. The mobile app provides step-by-step guidance for tasks like receiving and picking, reducing the learning curve. Even new hires can be productive within days, and training is faster compared to legacy systems. - How long does it take to implement warehouse management in D365 F&SCM?

Implementation timelines for Dynamics 365 Supply Chain Management vary based on project scope and complexity. A full deployment typically takes 6 to 24 months, depending on the number of locations, level of automation, and required integrations. Rand Group follows a phased implementation approach to ensure measurable progress and deliver value throughout the project lifecycle. - Is D365 SCM warehouse management suitable for smaller businesses or only for large enterprises?

D365 Supply Chain Management is recommended for mid to large size organizations. Mid-sized businesses can start with basic setups and expand over time, while larger enterprises can manage complex, multi-site operations. For less complex needs, Business Central may be a better fit. - What other systems or modules can D365 SCM’s Warehouse Management integrate with?

It integrates natively with modules like procurement, production, sales, transportation, and finance. It also connects with other Dynamics 365 apps, Microsoft Power Platform, third-party logistics, and IoT devices for extended functionality.

Next Steps

Warehousing is no longer a back-office function, it is a strategic driver of customer satisfaction, efficiency, and growth. Dynamics 365 Supply Chain Management’s warehouse management module enables businesses to modernize their warehouses, unify their processes, and achieve greater accuracy and speed.

Contact Rand Group today to see how Dynamics 365 Finance & Supply Chain Management can transform your warehouse operations into a strategic asset for long-term success.