Introduction to manufacturing in Dynamics 365 Business Central

Manufacturing excellence is no longer defined by output alone—it’s driven by how efficiently and intelligently you connect every part of your operation. Small and midsize manufacturers are under increasing pressure to reduce costs, meet fluctuating demand, and maintain high product quality — all while managing limited resources. Microsoft Dynamics 365 Business Central provides a unified solution that connects every aspect of manufacturing, from planning and production to costing and delivery. This guide introduces how Business Central’s built-in manufacturing capabilities can help you streamline operations, improve accuracy, and scale for growth.

In this blog, we will explore the following topics:

What is Business Central?

Microsoft Dynamics 365 Business Central is a modern, all-in-one ERP platform that unifies finance, supply chain, operations, and manufacturing. Designed for small and midsize businesses, it helps organizations replace disconnected systems with a single, intelligent solution that provides real-time visibility across all departments.

For manufacturers, Business Central provides the flexibility and scalability to manage everything from materials planning to production scheduling. It brings together critical manufacturing data—items, routings, resources, and costs—so that you can make faster, more informed decisions and maintain efficiency from order to delivery.

The power of manufacturing in Business Central

Manufacturing remains the engine of the global economy, driving innovation and productivity across every industry. But in today’s competitive market, manufacturers must respond quickly to changing demands while maintaining operational excellence. That’s where Business Central’s manufacturing module excels.

Business Central’s manufacturing capabilities aren’t just an add-on—they’re a powerful, integrated system designed to help you plan, produce, and deliver with confidence. Here are the key components that form its foundation:

- Bills of Material (BOMs): Think of the BOM as the recipe for your product. It defines all components required—from raw materials to subassemblies—and specifies the quantities needed.

- Routings: These define the exact process for creating the product, including each operation, tool, and resource used.

- Work centers: Represent the physical or logical resources that execute operations, such as machines, labor pools, or subcontractors.

- Production orders: Serve as the command center for manufacturing, coordinating every step from material consumption to finished goods posting.

Practical example: The cake analogy

To simplify the concept, imagine you’re running a bakery. Your product is a cake, and your manufacturing process looks like this:

BOM: The recipe: listing flour, eggs, sugar, and icing as components.

Routing: The steps: mixing, baking, cooling, and decorating.

Work Centers: The oven (machinery), decorators (labor), and cooling racks (subcontractors).

Production Order: A guide for making 10 cakes based on a customer order.

Together, these features form a unified ecosystem. Business Central seamlessly connects planning, scheduling, production, and costing—ensuring that every team operates from the same source of truth.

Now that we’ve covered the foundational capabilities of Business Central, let’s look at how manufacturing begins with your master data.

Setting the stage: master data in Business Central

Before production can begin, manufacturers need accurate and consistent master data. This information serves as the backbone of every operation, defining materials, components, and processes.

What is master data?

Master data represents the backbone of manufacturing and includes:

- Item master data: Defines all finished goods, subassemblies, and raw materials

- Bills of material (BOMs): Detail the components and quantities needed to create a product

- Routings: Outline the operations and resources needed to transform components into finished goods

Step 1: Item Master Data

Every manufacturing journey starts with setting up your item master data, which defines your products’ characteristics, including:

- Base unit of measure: For example, you may produce items in pieces, kilograms, or meters.

- Costing methods: Choose from FIFO, standard, or average costing to ensure accurate cost tracking.

- Planning parameters: Define safety stock levels, reorder points, and lead times to maintain balance between supply and demand.

- Inventory and costing details: Choose a costing method such as FIFO, standard, or average. For most manufacturers, FIFO or standard costing provides the most accurate.

Step 2: Bills of Material (BOMs)

Think of the Bill of Material (BOM) as your product’s recipe — every ingredient must be measured and listed before production begins. The BOM defines each component and the exact quantities needed to create your finished item.

- BOMs: Detail the raw materials and quantities required for each finished item.

- Routings: Define the operations needed to build that item

Example: When baking a chocolate cake, your BOM would include flour, sugar, cocoa powder, eggs, butter, and frosting — each with precise measurements. In manufacturing terms, those ingredients translate to raw materials or subassemblies. Just as a missing ingredient can ruin the cake, an inaccurate BOM can halt production or increase waste.

Tip: Always verify BOM accuracy before production begins. Even a missing component can cause costly interruptions.

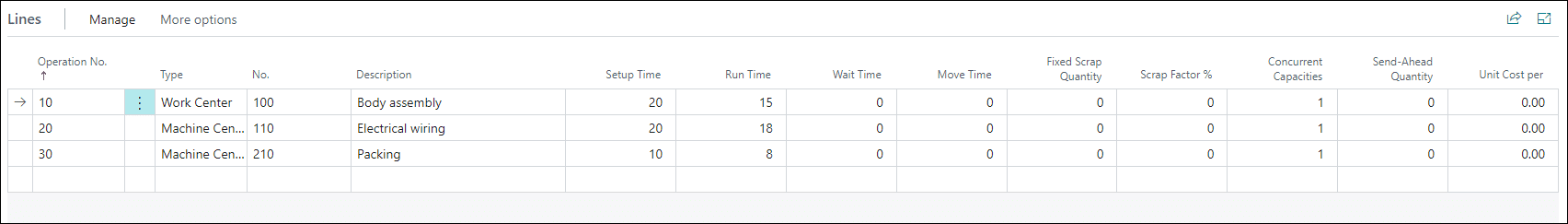

Step 3: Routings

Routings describe the sequence of operations to manufacture your product. Each step is linked to a work center or machine and includes setup and run times.

Example:

- Mixing ingredients (Work Center: Mixer)

- Baking (Work Center: Oven)

- Decorating (Work Center: Decorator)

Accurate master data supports efficient production, ensures cost control, and enables scalability as your business grows.

Step 4: Deliver the finished product

Once production is complete, Business Central automatically moves the finished goods into inventory, making them available for sale or distribution. This seamless transition from production to fulfillment ensures real-time visibility across departments and accurate financial reporting. Accurate master data supports efficient production, ensures cost control, and enables scalability as your business grows.

Optimize your manufacturing process with Business Central

See how integrated BOMs, routings, and production orders drive visibility and efficiency. Experience a live walkthrough of Business Central’s manufacturing module.

Once your master data is in place, production orders become the operational heartbeat of your manufacturing environment. They bring together all the pieces—BOMs, routings, resources, and capacity—to coordinate production from start to finish.

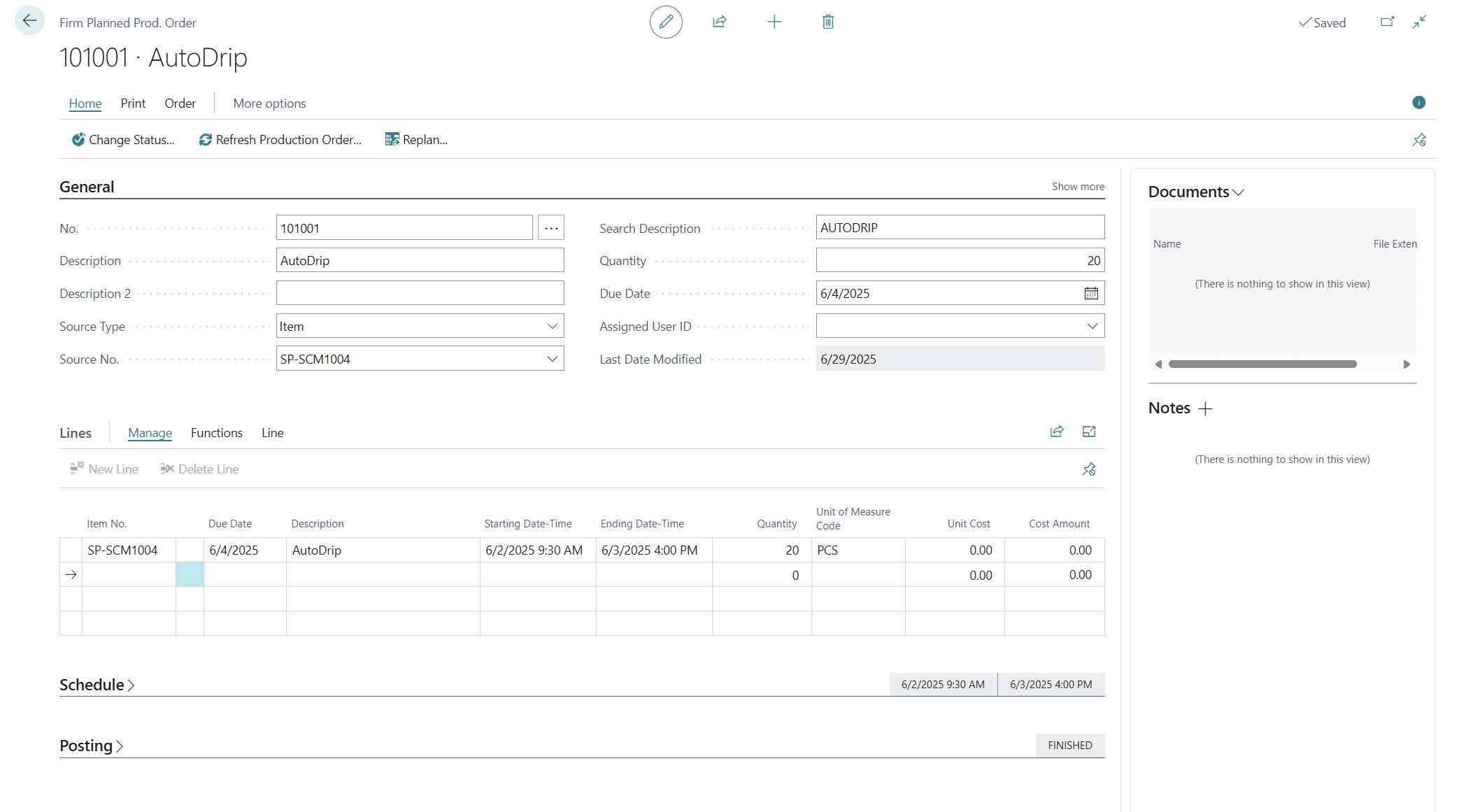

Understanding production orders

A production order isn’t just documentation; it’s a dynamic command center. Business Central supports several order types:

- Simulated orders: Used to test various scenarios without affecting inventory

- Planned orders: Automatically created by MRP based on demand forecasts

- Firm planned orders: Converted from planned orders for execution

- Released orders: Sent to the shop floor for active production

- Finished orders: Marked complete once goods are produced and inventory updated

Create production orders

Production orders bring your plans to life. These can be generated manually or automatically using Business Central’s built-in Material Requirements Planning (MRP) tool. MRP reviews forecasts, inventory, and lead times to recommend when and what to produce, helping manufacturers align production schedules with real demand.

Manage the production process

As work progresses, Business Central allows you to track each operation through your defined work centers. Labor and material usage are recorded through journals such as:

- Consumption journal: Tracks raw materials consumed during production

- Capacity journal: Records labor hours and machine time used per operation

This visibility ensures every stage of production is monitored and accurately costed, helping you maintain control over resources, timelines, and profitability.

How flushing methods work

Flushing methods define when and how materials and labor are recorded:

- Manual flushing: Operators enter actual usage data after production

- Backflushing: The system automatically posts consumption based on BOM and routing data at the time of completion

Example: With manual flushing, operators record how much flour, sugar, and time were used after mixing. With backflushing, the system automatically assumes standard quantities and time based on your predefined recipe once baking is complete.

Managing production efficiently

To ensure smooth production order management:

- Start with firm planned orders to validate BOMs and routings

- Use MRP to generate planned orders aligned with real demand

- Record actual usage through production journals to maintain costing accuracy

Production orders in Business Central give teams the flexibility to balance automation with control—so operators can focus on output instead of administration.

Why small and medium manufacturers love Business Central

Unlike many legacy ERP systems, Business Central is designed with SMBs in mind. Its manufacturing features are powerful yet approachable, allowing smaller businesses to gain enterprise-grade functionality without enterprise-level complexity.

Benefits include:

- Scalability: Start with core manufacturing features and add advanced modules such as MRP and capacity planning as you grow

- Customization: Tailor dashboards, workflows, and reports to fit your exact needs

- Cloud integration: Operate from anywhere with secure, browser-based access

This flexibility empowers SMBs to achieve efficiency and innovation while keeping costs manageable.

Comparing Business Central to traditional ERP systems

Traditional ERP systems often separate manufacturing from financials or require costly integrations. Business Central brings it all together:

- Integrated financials: Manufacturing transactions automatically update the general ledger for real-time costing

- Automated MRP: Plan materials and production automatically based on sales orders, inventory, and lead times

- Built-in Power BI: Access rich visual Power BI dashboards to analyze costs, capacity, and performance trends

By unifying all these components, Business Central reduces errors, increases accuracy, and provides full operational transparency.

Featured Video:

Microsoft Dynamics 365 Business Central Manufacturing Series Part I – Manufacturing Concepts

Get a visual walkthrough of how Business Central brings your manufacturing processes together. In this video, you’ll see how Bills of Material (BOMs), routings, and production orders work in harmony to streamline operations, improve visibility, and enhance efficiency across your shop floor.

Transforming manufacturing with Rand Group

Manufacturing success depends on precision, agility, and insight — all of which Dynamics 365 Business Central delivers. From defining master data and managing BOMs to executing production orders and tracking costs, Business Central provides an end-to-end framework that keeps your operations connected and efficient.

For growing manufacturers, it’s not just a system; it’s a strategy for sustainable success. With its cloud flexibility, scalability, and integration with Microsoft’s intelligent ecosystem, Business Central helps organizations operate smarter and plan confidently for the future.

At Rand Group, we help manufacturers unlock the full potential of Microsoft Dynamics 365 Business Central. Our team of experts specializes in implementation, optimization, and ongoing support — ensuring your system aligns perfectly with your production goals.

Contact Rand Group to schedule a personalized consultation and see how Business Central can transform your manufacturing performance.